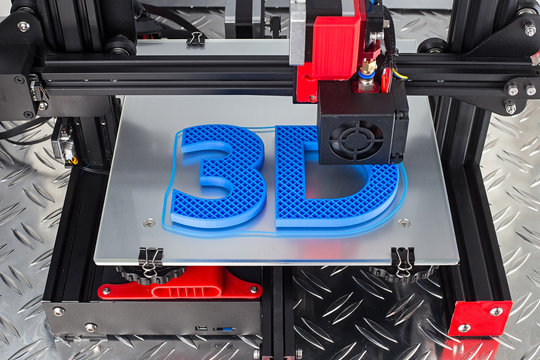

3D printing has transformed the way we design, prototype, and manufacture products across various industries. However, as many professionals in the field know, the process doesn’t end once the print is complete. Post-processing is a critical step that can significantly impact the quality, functionality, and aesthetic of the final product. This is where Omegasonics ultrasonic cleaners come in. Offering unmatched precision, efficiency, and ease of use, these cleaners have become essential tools for anyone looking to streamline their 3D printing workflow.

The Challenges of 3D Printing Post-Processing

After a 3D object is printed, it often requires a series of finishing steps to reach its full potential. Common post-processing tasks include:

- Removing Support Material: Support structures are essential for certain 3D prints, but they can be challenging to remove without damaging the final product.

- Surface Smoothing: Many prints have rough surfaces, seams, or layer lines that need to be smoothed for a polished finish.

- Cleaning Residue: Depending on the printing material, there may be leftover resin, powder, or other residues that need to be cleaned.

Traditional post-processing methods, such as manual sanding, scraping, and chemical baths, can be time-consuming, inconsistent, and potentially harmful to the printed parts. That’s why many professionals are turning to ultrasonic cleaning as a faster, safer, and more effective alternative.

How Omegasonics Ultrasonic Cleaners Work

Omegasonics ultrasonic cleaners use high-frequency sound waves to create millions of microscopic bubbles in a liquid cleaning solution. When these bubbles burst, they release a powerful yet gentle scrubbing action that dislodges dirt, support material, and residues from the surface of the object. This process, known as cavitation, reaches into every nook and cranny of the part, ensuring a thorough and even clean.

Why Choose Omegasonics for 3D Printing Post-Processing?

Omegasonics is a leader in ultrasonic cleaning technology, and its machines are specially designed to meet the unique challenges of 3D printing post-processing. Here are a few reasons why Omegasonics ultrasonic cleaners stand out:

- Precision Cleaning Without Damage

One of the main advantages of ultrasonic cleaning is its ability to clean even the most delicate and complex parts without causing damage. Whether you’re working with intricate geometries, fine details, or fragile materials, Omegasonics ultrasonic cleaners can remove support material and other residues without compromising the integrity of the part.

- Faster and More Efficient Than Manual Methods

Traditional methods of support removal and cleaning can take hours, especially for parts with complex geometries. Omegasonics ultrasonic cleaners drastically reduce the time required for these tasks, often completing them in a matter of minutes. This means faster turnaround times and increased productivity, allowing you to focus on creating more prints.

- Environmentally Friendly Cleaning Solutions

Omegasonics understands the importance of sustainability. That’s why our ultrasonic cleaners use environmentally friendly, water-based cleaning solutions that are safe for both users and the planet. These solutions are non-toxic, biodegradable, and free of harsh chemicals, making them a safer choice for your workspace.

- Consistent and Reliable Results

When it comes to post-processing, consistency is key. Omegasonics ultrasonic cleaners ensure that every part is cleaned to the same high standard, eliminating the variability that often comes with manual cleaning methods. This level of reliability is essential for businesses that need to maintain high-quality standards across multiple prints.

- Ease of Use

Omegasonics ultrasonic cleaners are designed with user-friendliness in mind. With intuitive controls, preset cleaning programs, and easy-to-follow instructions, these machines can be operated by anyone, regardless of their level of experience. This makes them ideal for both hobbyists and large-scale production facilities.

Applications of Omegasonics Ultrasonic Cleaners in 3D Printing

Omegasonics ultrasonic cleaners can be used to streamline a variety of post-processing tasks in 3D printing, including:

Support Material Removal

- FDM/FFF Printing: Ultrasonic cleaners are highly effective for dissolving soluble support materials like PVA or HIPS. This is particularly useful for parts with complex overhangs and internal cavities that are difficult to reach with traditional tools.

- SLA/DLP Printing: For resin-based printing, ultrasonic cleaners can quickly remove residual uncured resin, ensuring a smooth and clean surface ready for final curing.

Surface Smoothing and Polishing

- SLS/SLM/DMLS Printing: Parts printed with powder-based technologies often have rough surfaces that need to be smoothed. Ultrasonic cleaning can help remove excess powder and improve the finish of the part, preparing it for further polishing or coating.

Removal of Powders and Residues

- MJF/Binder Jetting: Ultrasonic cleaners can effectively remove loose powder and binding agents from parts printed with multi-jet fusion and binder jetting processes. This ensures the part is clean and ready for additional post-processing steps, like dyeing or sealing.

Choosing the Right Omegasonics Ultrasonic Cleaner for Your Needs

Omegasonics offers a range of ultrasonic cleaners, each designed to cater to different needs and scales of operation. From compact, tabletop units perfect for hobbyists and small businesses, to larger, industrial-scale machines for mass production environments, there’s an Omegasonics solution for every application. Some of the popular models include:

- Pro Series Tabletop Units: Ideal for small to medium-sized parts, these units offer a compact design without compromising on cleaning power.

- Industrial Cleaners: Designed for larger parts and higher volumes, the iSeries provides robust cleaning capabilities for demanding applications.

- Custom Solutions: For businesses with unique cleaning requirements, Omegasonics can design and build custom ultrasonic cleaning systems tailored to specific needs.

Tips for Effective Ultrasonic Cleaning in 3D Printing Post-Processing

To get the most out of your Omegasonics ultrasonic cleaner, consider the following best practices:

- Select the Right Cleaning Solution: Use a water-based solution recommended by Omegasonics that is compatible with your printing material and the type of residue you need to remove.

- Optimize Cleaning Time and Temperature: Different materials and residues require different cleaning parameters. Experiment with time and temperature settings to find the optimal combination for your specific prints.

- Rinse and Dry Thoroughly: After cleaning, rinse the parts to remove any remaining solution, and allow them to dry completely before further processing.

- Regular Maintenance of the Cleaner: Keep your Omegasonics cleaner in peak condition by following the maintenance guidelines provided in the user manual. Regularly check the tank and change the cleaning solution as needed.

Get Started with Omegasonics Ultrasonic Cleaners Today

Whether you’re a hobbyist or a professional in the 3D printing industry, Omegasonics ultrasonic cleaners can help you achieve superior results with less effort. Save time, reduce waste, and improve the quality of your 3D-printed parts by incorporating ultrasonic cleaning into your post-processing workflow.

Contact Omegasonics Today to Learn More!

For more information on our ultrasonic cleaners and how they can enhance your 3D printing process, call 888-989-5560 or email us . Our experts are here to help you find the perfect solution for your post-processing needs.

Omegasonics – Where Precision Meets Innovation