Ultrasonic Cleaning Keeps Firefighters Safer

PPE is the acronym for Personal Protection Equipment which describes any article of clothing a firefighter wears when battling a fire. Soft materials such as pants and jackets are effectively cleaned in a washing machine but hard materials such as helmets, boots, SCBA gears and some protective jackets are more effectively cleaned with ultrasound using NFPA 1851 approved chemistry.

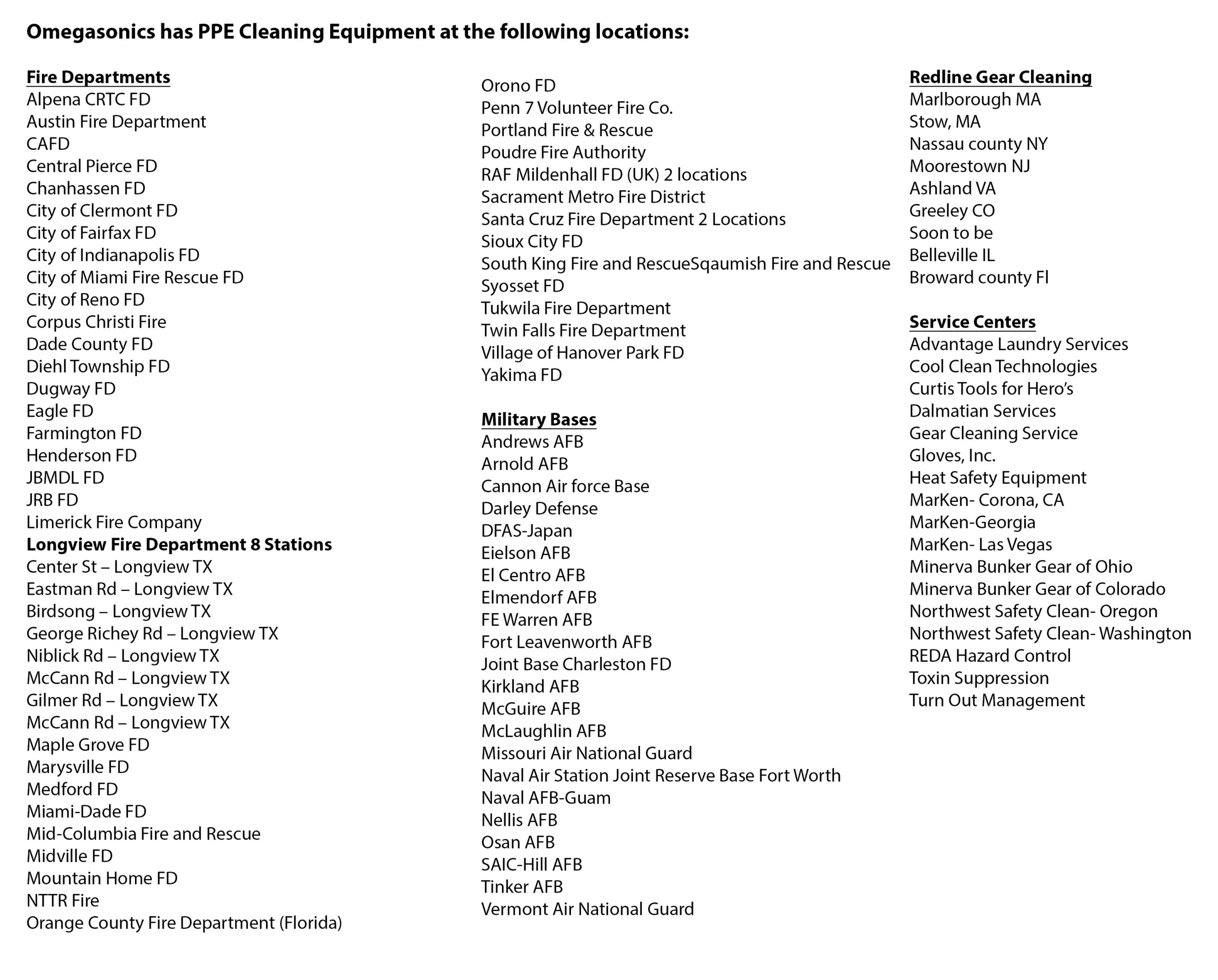

For a list of companies that have Omegasonics PPE cleaning equipment click here>>>

Video Gallery

Tough firefighters with dangerous jobs need equipment that’s clean and safe.

For first-responders, equipment that works often means the difference between life and death. For this reason NFPA 1851’s care standards are high. Two companies have found a way to meet these critical benchmarks and provide clean, safe personal protective equipment (PPE) to firefighters across the West.

MARKEN® PPE Restoration based in Las Vegas specializes in the inspection, cleaning, and repair of personal protective ensembles and ensemble elements used for structural, proximity, wildland, technical and emergency rescue operations. MARKEN® PPE Restoration founders knew from previous experience that firefighters encounter a wide variety of materials during a search or rescue call, and they often become caked or cooked on to intricate helmets, bulky rubber boots and delicate SCBA face masks. Hand scrubbing can’t provide the meticulous cleaning expected by the industry. It also requires a lot of man-hours, especially for helmet disassembly and reassembly, which negatively affects the bottom line.

Decreased helmet cleaning times by 75%

MARKEN® PPE Restoration incorporated Omegasonics’ ultrasonic cleaning technology into its services starting with its launch in 2010. It has decreased helmet cleaning time by 75 percent and employee training time by more than 85 percent. Learning how to disassemble and reassemble a wide variety of helmets used to require up to 30 hours, but training to use simple Omegasonics’ machines (that do not require disassembly or reassembly of equipment) needs only four. The company worked closely with fabric manufacturer Gentex and Omegasonics to find a way to clean fragile aluminized proximity suits gently and thoroughly.

Offering faster delivery time and the highest-quality cleaning has resulted in a high level of customer satisfaction. Without fail, they tell us they appreciate our use of the ultrasonic technology and how much more secure they feel with equipment that is clean and structurally sound.

– Joey Beeman, COO MARKEN® PPE Restoration

Labor Cost Savings of $10 per helmet

Northwest Safety Clean in Portland and Kent, Washington, has been around for 20 years and specializes in cleaning, repairing, altering and fabrication of firefighter turnouts and PPE. For years, cleaning boots and helmets required a lot of hand scrubbing, and fragile aluminized proximity suits had to be hand washed. During a trip to Las Vegas for a trade conference, Steve saw a presentation by Omegasonics president Frank Pedeflous and discovered there was a better way. He walked up to Frank afterwards and said, “I want one.”

Using their ultrasonic cleaning machine, Northwest Safety Clean cut helmet cleaning time from 15 minutes per helmet to five minutes, offering an estimated labor cost savings of $10 a helmet. Washing boots and helmets still requires some hand scrubbing, but their ultrasonic unit loosens or removes even the toughest substances in every crevice. Proximity suits are thoroughly cleaned in a temperature-controlled environment without compromising their structural integrity or effectiveness – a claim verified by the fabric manufacturer.

Honestly, initially I was interested in ultrasonic because I like new gadgets and electronics, and it just sounded cool. But it turned out to be a positive tool for my business. Also, I’ve been able to pass along the savings I’ve experienced on helmet cleaning to my customers. Fire departments need a lot of bang for their buck these days. Now they are more likely to send in their helmets for cleaning and inspection.

– Steve Lakey, Owner & CEO, Northwest Safety Clean

Cleaner, safer equipment means greater safety for us all…

Our ultrasonic PPE cleaners are available in a wide variety of sizes to meet your station or company needs. They all offer the same benefits:

- Cleaner helmets, boots, gloves, Level A suits and SCBA gear

- All systems qualified under NFPA 1851

- More affordable and less stressful for materials than hydraulic washers

- Helps maintain material integrity over time

- Decreases microbial exposure and risk of burns

- Cleans even very fragile material thoroughly and safely without hand washing

Video

Firefighters have cancer rates well above the general public due to many factors including wearing gear that permeates smoke, gas and toxins which absorb into their skin and lungs. Ultrasonic cleaning of helmets, boots, gloves, SCBA gear and tools is documented to be more thorough than standard hand cleaning.

Article

Learn how firefighters are winning the battle against carcinogens with ultrasonic cleaning. When it comes to removing toxins and carcinogens, if done properly, the ultrasonic cleaning process does a more thorough job of cleaning firefighting PPE and removing harmful contaminants than hand washing alone.