How does ultrasonic cleaning and cavitation work?

Ultrasonic cleaning is a process that uses ultrasound or sound waves (usually from 20–400 kHz) and an appropriate cleaning solution (sometimes ordinary tap water) to clean items. The ultrasound can be used with just water, but use of a cleaning agent appropriate for the item to be cleaned and the type of soiling present enhances the effect. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned. The ultrasound produces a cleaning energy called cavitation that makes cleaning hard durable objects more efficient and a better quality cleaning.

How Does ultrasonic cavitation work?

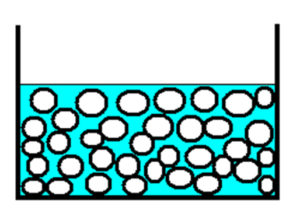

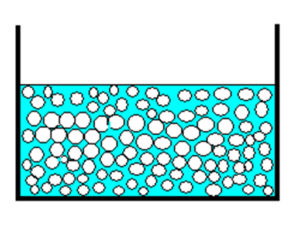

Ultrasonic cavitation is the cleaning bubble formed from different frequencies produced in a liquid to produce compression wave molecules compressed tightly together then expansion wave molecules are pulled apart from each other and penetrate deep into inaccessible areas, implosion releases energy heat and the jet of liquid imploding bubbles are the scrubbing mechanism formed and grow rapidly.

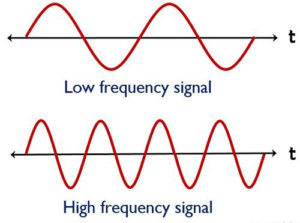

What are the different ultrasonic cleaning frequencies?

Normal range of human hearing 18Hz to 22kHz, Common frequencies from 25kHz to 80kHz Ultrasonic cleaning frequency must match the

cleaning application. Different frequencies produce different results.

Low frequency ultrasonic cavitation such as 28 kHz creates Larger bubbles, but fewer of them that Aggressive bubbles

For heavy duty Industrial applications.

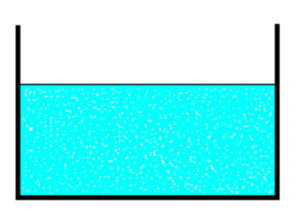

High frequency ultrasonic cavitation 40-80 kHz and up Very tiny bubbles packed tightly together gentle scrubbing action great For cleaning semi-conductors

And high end electronic components.

Medium frequency ultrasonic cavitation 40kHz produces smaller bubbles, but more of them and still produces powerful cleaning cavitation

What produces this ultrasonic cavitation in an ultrasonic cleaner?

There are four things that are needed for an ultrasonic cleaner to produce ultrasonic cavitation cleaning energy. The first item is a ultrasonic generator and the second one is a ultrasonic transducer or piezoelectric crystals and the third is an ultrasonic tank to hold the liquid and the forth is liquid.

What is a ultrasonic generator?

Ultrasonic generators are like stereo amplifiers, they send sound waves to the transducer that produces cavitation energy inside the water. Ultrasonic generators come in various wattage and frequency depending on your cleaning application and tank size.

What is a ultrasonic transducer?

Ultrasonic transducers are like having a stereo speaker in the water that omits sound waves that creates the cleaning cavitation. There are 2 different types of transducers used for cleaning, the first one is a bonded plate with piezoelectric crystals, other style is a immersible transducer pack. The immersible ultrasonic transducer is a stainless steel enclosure filled with piezoelectric crystals, the amount of crystals depends on the wattage of the transducer. Below is an example of a immersible transducer.

The other factors that affect cleaning results are:

- Power

- Heat

- Time

- Ultrasonic Cleaning Solution

Power is the amount of power that the generator generates and sends to the transducers.

Heat is required for better cleaning results and also speeds up the cleaning process.

Time varies depending on the time of item that you are cleaning and the type of contamination, rust, dirt, oil or grease that is on the item.

Ultrasonic Cleaning Solutions Cleaning effectiveness of an ultrasonic unit can be altered by the solutions utilized. Omegasonics’ cleaning solutions are formulated for specific cleaning applications and are designed for ultrasonic cleaning and do not break down from heat and cavitation.

The most common industries That Use Ultrasonic Cleaning are:

- Industrial

- Medical

- Automotive

- Marine

- Aerospace

- 3D Printing

- Machining

- Food & Drug

- Fire Restoration

- Firearms

- Jewelers

- Military

- Blind Cleaning

- Musical Instruments

This is just to name a few, the use of ultrasonic cleaning keeps growing as more and more companies find it to be a more:

- Efficient – Ultrasonic cleaning provides the ability to clean baskets of parts rather than individual items.

- Thorough – Ultrasound is the most thorough cleaning method known to science. Contents cleaned manually by hand will never be as clean as contents processed ultrasonically. Ultrasonic bubbles can reach areas impossible to access by brushes or sponges.

- Gentle – The ability to control the cleaning variables allows the same equipment to clean everything from industrial parts to delicate crystal and china.

- Consistent – Cleaning with ultrasonics is always consistent.

What can be cleaned in an ultrasonic cleaner?

The main factor for an item to be able to be cleaned in an ultrasonic cleaner is: is the item hard and durable? Such as glass, plastic, ceramic and metal.

The number of items that can benefit from ultrasonic cleaning is vast. The reason? There are just two basic “eligibility requirements” before something can be cleaned in this manner.

The cavitation that powers ultrasonic cleaning and scrubs contaminants off parts will only occur in a liquid environment. Ergo, the item must be one that won’t be damaged by immersion. Some of the things on that list might surprise you. For instance, most of us would react with horror at the idea of combining electronics and water, but as long as proper drying techniques are used, an ultrasonic cleaner will not only clean electronic devices, but clean them more quickly and completely than any other method.

The second requirement is that the part can be dried relatively easily. This eliminates items that are absorbent, but most others can simply be air dried with a blower.

For this reason, ultrasonic cleaning is used to remove unwanted materials from everything from jewelry to long rifles, from super-delicate lenses to massive engine parts, from surgical instruments to motherboards.

You may be wondering if ultrasonic waves will damage relatively brittle materials, such as glass or ceramics. Ultrasonic cleaning is perfectly safe for these materials.

What about electronics? Can electronic items such as computers, laptops and TV’s be clean in an ultrasonic cleaner?

The only electronic items that can be cleaned in an ultrasonic cleaner are simple electronics that do not have any type of LED or LCS screen, internal battery or power source and does not need to be re-oiled or greased. These items are toasters, saws, fans, blow dryers and drills. Never put a computer or laptop in an ultrasonic cleaner, due to many factors. They have thermal paste on both the processor and the graphics processor that the ultrasonic cavitation will remove.

Here is a list of factors to consider if an electrical item can be successfully cleaned in a ultrasonic tank.

- Does the electronic have a display screen?

- Does it need to be re-oiled or greased?

- Does it have glass that can trap moisture?

- Does it have wood or cloth?

- Does it have a internal power source such as battery or capacitor?

If the answer is yes to any of these on the electronic item that you are trying to clean then do not put it in the ultrasonic cleaner.

Electronics cleaning always requires a de-ionized water rinse also, due to the fact that regular tap water has minerals in it that will corrode the electronics and make it not function as it once did.

Here are some examples of ultrasonic cleaners from small to large depending on your cleaning application:

ProLite Ultrasonic Cleaner

The ProLite ultrasonic cleaner is a smaller 20 gallons cleaner. That is used in smaller cleaning applications.

Pro Plus Ultrasonic Cleaner

The Pro Plus ultrasonic cleaner has a 33 gallon tank for medium cleaning applications.

Power Pro 8000 Ultrasonic Cleaner

The Power Pro 8000 ultrasonic cleaner features a large 110 gallon cleaning tank for larger applications.

This is only a few ultrasonic cleaner examples, we have many different size tanks and even custom tanks for larger industries like aerospace, mold and die and the oil industry.

Below is a video on how an ultrasonic cleaners works.