- Dissolving Contaminants:Cavitation, the formation and violent collapse of microscopic bubbles in the cleaning fluid induced by ultrasonic waves, creates intense local cleaning action. However, it is the solvent that breaks down and dissolves the contaminants. The choice of solvent depends greatly on the type of contaminants being removed.

- Lubrication and Heat Transfer:Solvents also act as a lubricating medium, which helps in dislodging contaminants easily from the object’s surface. This lubrication is crucial in preventing the redeposition of loosened particles back onto the surface. Additionally, ultrasonic cleaning solutions assist in transferring the heat generated by ultrasonic waves, further enhancing the cleaning action.

- Reduced Surface Tension:Many ultrasonic cleaning solutions contain surfactants that reduce the surface tension of the liquid. Lower surface tension allows ultrasonic waves to penetrate more deeply and clean more thoroughly, which is especially important when cleaning complex or highly detailed objects. This feature helps in reaching contaminants lodged within tiny crevices or intricate features of the objects being cleaned.

- Rinsing and Drying:After the cleaning process, solvents facilitate the removal of any residual contaminants and cleaning agents from the object’s surface. Certain solvents also evaporate quickly during the drying process, which helps in leaving the object clean and dry.

- Reduced Cleaning Effectiveness: The most straightforward indicator that the solution needs changing is a noticeable drop in cleaning performance. If the solution cannot remove contaminants as effectively as before, it may be saturated and require replacement.

- Visibility and Transparency: A visible change in the solution’s clarity often suggests contamination. If the solution appears murky or has visibly changed color, it’s a sign that it might be time for a replacement.

- Conductivity Changes: Measuring changes in the solution’s conductivity can indicate contamination levels. However, this method may not always be reliable, as different contaminants affect conductivity in varying ways.

- High-Frequency Ultrasonic Wave Speeds: A novel method involves measuring the speed of high-frequency ultrasonic waves through the solution. Changes in wave speed can indicate changes in the solution’s composition and effectiveness, although variations in raw materials can affect the accuracy of this method.

- Type of Contaminants: Heavily contaminated parts may necessitate more frequent changes as the solution quickly becomes saturated.

- Volume and Type of Cleaning: Frequent cleaning or cleaning very fine or sensitive items might require more regular solution changes to maintain a high standard of cleanliness.

- Use of Filtration Systems: Implementing filtration systems can extend the life of cleaning solutions, reducing the frequency of changes. Filtration can be particularly cost-effective for larger tanks or heavily used systems.

- What is the recommended cleaning solution for ultrasonic cleaners? We suggest using OmegaSupreme, our most versatile and industrial friendly cleaning detergent utilizing all the newest technologies in chemistry. Perfect for removing oils, light grease, dirt, grime, carbon and other contaminants from a wide variety of metals. Stainless steel, titanium, carbon steel, and plastics. Non-HAZMAT.

- How do I select the appropriate ultrasonic cleaner for my needs? To choose the best ultrasonic cleaner, consider several key factors including the frequency and power level of the unit, the size of the tank, the type of cleaning solution required, and whether you will need to use heat. These considerations will help you find a system that fits your specific cleaning needs.

- Are there differences in the effectiveness of various ultrasonic cleaners? Yes, the effectiveness of an ultrasonic cleaner largely depends on its ultrasonic power and frequency. Generally, a higher power and a lower frequency contribute to greater cleaning efficiency.

- Should I use tap water or distilled water in my ultrasonic cleaner? You can use regular tap water in your ultrasonic cleaner without issues. Distilled water will yield similar results to tap water, though using deionized water can help in preventing streaks on the items being cleaned.

-

Choosing the right ultrasonic cleaner solution is crucial for the optimum performance of your ultrasonic cleaning system. The effectiveness of the cleaning process heavily depends on using a solution that is compatible with both the items being cleaned and the ultrasonic cleaner itself. With the myriad of ultrasonic cleaning solutions available on the market, selecting the appropriate sonic cleaner solution can significantly enhance the efficiency and longevity of the cleaning process. Understanding the science behind ultrasonic cleaner solutions and how they work in conjunction with ultrasonic energy to remove contaminants is the first step towards achieving superior cleaning results.

This article delves into the factors to consider before selecting an ultrasonic cleaner solution, the different types of solutions available, and provides application-specific recommendations to guide users in making an informed decision. Furthermore, it highlights common mistakes to avoid and best practices for using ultrasonic cleaner solutions, ensuring users get the most out of their ultrasonic cleaning systems. Whether you’re a novice or an experienced user, understanding when to change your cleaning solution for ultrasonic cleaner and adhering to these guidelines can lead to more effective cleaning outcomes and prolong the lifespan of your equipment.

Understanding the Importance of Ultrasonic Cleaner Solutions

Understanding the role of solvent cleaners is crucial to one’s expertise in the ultrasonic cleaning process. These cleaners perform several key functions that enhance the effectiveness of ultrasonic cleaning systems. Here are the primary roles they play:How Ultrasonic Cleaner Solutions Work

The Process of Cavitation

Cavitation is the cornerstone of how ultrasonic cleaner solutions function. This phenomenon involves the rapid creation and collapse of tiny vacuum bubbles in the cleaning liquid. When these bubbles collapse, they generate a powerful “scrubbing” action against the surfaces of the objects being cleaned. These microscopic bubbles implode with significant force, dislodging dirt and contaminants effectively. The cavitation process starts with the generation of ultrasonic energy, which creates alternating high and low-pressure waves in the cleaning liquid. As the liquid experiences these pressure fluctuations, cavities or vacuum bubbles form during the low-pressure phase and grow to a critical size before collapsing during the high-pressure phase. The implosion of these cavities releases a tremendous amount of energy, localized at a microscopic level, which is safe yet powerful enough to clean delicate parts without causing damage. This localized energy release can reach temperatures and pressures exceedingly high, which further aids in the effective cleaning of the objects.Role of Ultrasonic Waves

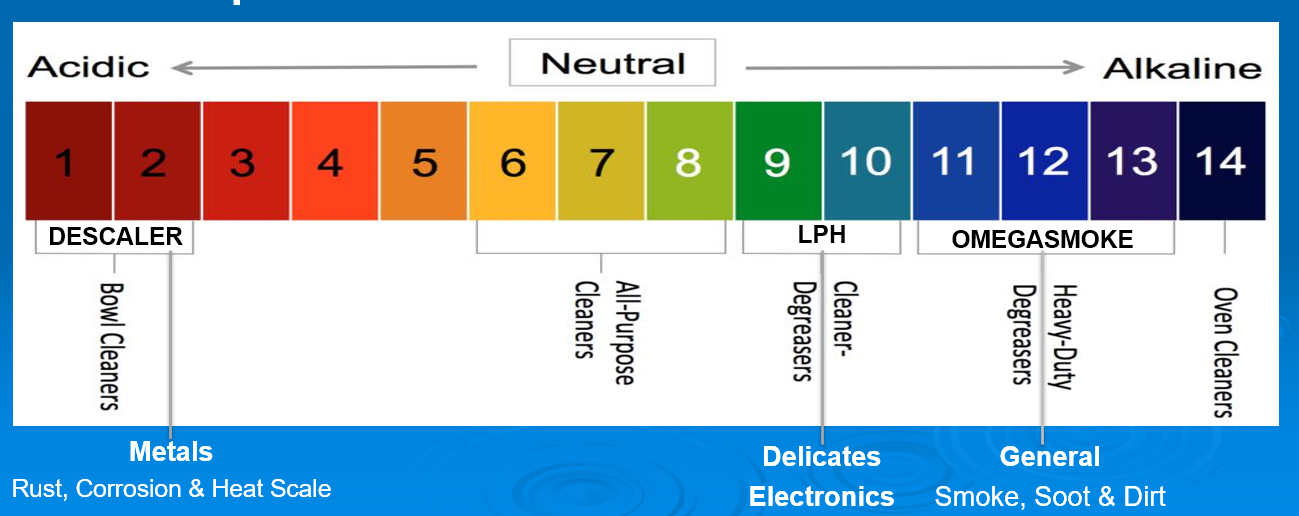

Ultrasonic waves play a pivotal role in the cleaning process by transmitting high-frequency sound waves through the cleaning solution, which agitates the liquid and enhances the formation of cavitation bubbles. The frequency of these ultrasonic waves is crucial as it determines the size of the cavitation bubbles and thus affects the cleaning efficiency. Higher frequencies generate smaller bubbles, suitable for cleaning intricate parts and removing smaller particles. Conversely, lower frequencies produce larger bubbles, which are more effective in dislodging larger contaminants but might pose a risk to delicate components. The interaction between the ultrasonic waves and the cleaning solution is also influenced by the solution’s properties, such as its surface tension and pH level. Solutions with lower surface tension improve the wetting ability of the liquid, allowing better contact with the object’s surface and enhancing the cavitation effect. Additionally, the pH of the solution can affect its cleaning effectiveness, with different pH levels tailored to remove specific types of contaminants more effectively. Through the precise control of ultrasonic wave frequencies and the chemical composition of the cleaning solution, ultrasonic cleaners can target various contaminants on diverse materials, providing a versatile and effective cleaning method.Factors to Consider Before Selecting a Solution

Types of Contaminants

When selecting an ultrasonic cleaner solution, it is crucial to identify the specific contaminants that need to be removed. These can range from organic compounds like grease, grime, and biological residues to inorganic compounds such as salts and mineral deposits. Additionally, some specialized applications may involve removing microbiological contaminants or residues from manufacturing processes like mold support from 3-D printed products or burnt-on deposits from plastic injection molds.Material of the Object

The material composition of the objects being cleaned significantly influences the choice of ultrasonic cleaning solution. Different materials respond differently to various cleaning agents. For instance, sensitive materials like aluminum or certain plastics may require milder solutions to prevent damage, while more robust materials like stainless steel can tolerate stronger alkaline solutions. It is essential to ensure that the selected solution is compatible with the material to avoid adverse reactions such as corrosion or discoloration.Nature of the Contaminant

The physical and chemical nature of the contaminant also plays a pivotal role in selecting the appropriate cleaning solution. Water-soluble contaminants might be effectively removed with mild detergents or even de-ionized water. In contrast, oil-based or non-water-soluble contaminants might require emulsifying or demulsifying solutions to ensure effective removal. Demulsifying solutions are particularly useful for separating oily contaminants, which float to the surface and can be skimmed off, whereas emulsifying solutions hold contaminants in suspension, suitable for low-volume cleaning operations. By considering these factors—types of contaminants, material of the object, and the nature of the contaminant—users can make informed decisions that enhance the effectiveness of the ultrasonic cleaning process while ensuring the longevity and safety of the materials being cleaned.Types of Ultrasonic Cleaner Solutions