Ultrasonic cleaners have become the go-to solution for efficient and thorough cleaning across a range of industries, from healthcare and automotive to electronics and jewelry. These powerful devices use high-frequency sound waves to remove dirt, grease, contaminants, and residues from a variety of objects, including intricate and hard-to-reach surfaces. This comprehensive guide will explain how ultrasonic cleaners work, their benefits, applications, and how to choose the right one for your needs.

What is an Ultrasonic Cleaner?

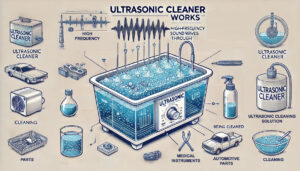

An ultrasonic cleaner is a device that uses high-frequency sound waves (typically ranging from 20 kHz to 400 kHz) to create microscopic bubbles in a cleaning solution. This process, known as cavitation, results in millions of tiny, high-energy bubbles forming and collapsing rapidly. The energy released during this process effectively loosens and lifts away dirt, grease, oil, and other contaminants from surfaces, providing a deep and thorough clean without damaging the items being cleaned.

Ultrasonic cleaners are particularly effective for cleaning complex parts with intricate designs, such as medical instruments, automotive components, electronic parts, and jewelry, where traditional cleaning methods might not reach.

How Does an Ultrasonic Cleaner Work?

- Filling the Tank: The cleaning tank is filled with a suitable cleaning solution, often a water-based solution with added detergents or solvents to enhance the cleaning effect.

- Loading the Items: Objects to be cleaned are placed in the tank, either directly or in a basket, ensuring they are fully submerged in the solution.

- Ultrasonic Cleaning Process: Once the device is turned on, it generates high-frequency sound waves that travel through the liquid, creating millions of tiny cavitation bubbles. When these bubbles collapse, they release bursts of energy that dislodge dirt, grease, and other contaminants from the surfaces of the submerged objects.

- Rinse and Dry: After the cleaning cycle is complete, the items are rinsed and dried, ready for use. The entire process is quick, efficient, and requires minimal manual intervention.

Visit How An Ultrasonic Cleaner Works Video For More Info>>>

Benefits of Using Ultrasonic Cleaners

- Efficient Cleaning: Ultrasonic cleaners provide fast and effective cleaning, capable of removing even the most stubborn contaminants from items. They are particularly effective for cleaning hard-to-reach areas, such as tiny crevices, joints, and intricate designs.

- Non-Abrasive and Gentle: Unlike traditional scrubbing or brushing, ultrasonic cleaning is non-abrasive. This makes it ideal for delicate items that could be damaged by harsher cleaning methods, such as jewelry, electronic components, and sensitive medical instruments.

- Saves Time and Labor: Manual cleaning can be time-consuming and labor-intensive, especially for complex parts. Ultrasonic cleaners automate the process, freeing up valuable time and reducing labor costs.

- Environmentally Friendly: Ultrasonic cleaners often use water-based solutions that are less harsh than traditional solvents. This not only reduces environmental impact but also improves workplace safety.

- Versatility: Ultrasonic cleaners can be used to clean a wide variety of items across different industries. They are effective for metals, plastics, ceramics, glass, and more.

Common Applications of Ultrasonic Cleaners

- Medical and Dental Instruments: Ultrasonic cleaners are widely used in the healthcare industry to clean surgical tools, dental instruments, and lab equipment. The ability to clean complex instruments quickly and thoroughly helps ensure hygiene and safety.

- Automotive Parts: From carburetors to fuel injectors, ultrasonic cleaners can remove grease, carbon deposits, and other contaminants from automotive components, extending the life of parts and improving vehicle performance.

- Jewelry Cleaning: Ultrasonic cleaners are a popular choice for cleaning jewelry, as they can effectively remove tarnish, dirt, and oils from intricate designs and settings without damaging delicate pieces.

- Electronics and Circuit Boards: Ultrasonic cleaning is ideal for cleaning electronic parts, such as circuit boards and sensors, as it can remove dust, solder flux, and other residues without causing damage.

- Industrial Applications: Ultrasonic cleaners are used for cleaning molds, dies, and machine parts in various industries. Their ability to remove grease, oil, and other contaminants ensures smooth operation and prevents equipment wear.

- Food and Beverage Industry: Ultrasonic cleaners can be used to clean food processing equipment, filters, and other components, ensuring they remain sanitary and free from contaminants.

Choosing the Right Ultrasonic Cleaner

When selecting an ultrasonic cleaner, consider the following factors:

- Size and Capacity: Choose a cleaner that can accommodate the items you need to clean. Small cleaners are suitable for jewelry and small parts, while larger models are needed for industrial equipment and automotive components.

- Frequency: The frequency of the sound waves determines how the cleaner will perform. Lower frequencies (20-40 kHz) are suitable for heavy-duty cleaning of items with tougher contaminants, while higher frequencies (above 40 kHz) are better for delicate items and intricate designs.

- Tank Material: Stainless steel tanks are durable and resistant to corrosion, making them ideal for long-term use.

- Cleaning Solution: Ensure the cleaning solution is compatible with the items you plan to clean. Some cleaners come with specific solutions designed for particular applications, such as jewelry cleaning or industrial degreasing.

- Timer and Temperature Control: Look for ultrasonic cleaners that offer adjustable timers and temperature controls, as this allows you to customize the cleaning process for different items and levels of contamination.

How to Use an Ultrasonic Cleaner Effectively

- Choose the Right Cleaning Solution: Select a cleaning solution that is appropriate for the items you are cleaning. Some solutions are specifically designed to tackle oils and grease, while others are gentle enough for delicate materials.

- Proper Loading: Ensure items are properly placed in the tank, fully submerged, and not stacked on top of each other, which can impede the cleaning process.

- Set the Correct Parameters: Adjust the frequency, time, and temperature settings based on the type of items you are cleaning. Refer to the manufacturer’s guidelines for recommended settings.

- Routine Maintenance: Regularly clean the tank and replace the cleaning solution to ensure consistent and effective results.

Conclusion

Ultrasonic cleaners have transformed the way industries clean and maintain their equipment, tools, and products. With their speed, efficiency, and ability to provide a deep clean, they have become an essential tool in various sectors. Whether you are looking to clean delicate jewelry, automotive parts, or medical instruments, ultrasonic cleaning offers a precise and reliable solution.

By understanding how ultrasonic cleaners work, their benefits, and how to choose the right one for your needs, you can ensure optimal cleaning performance and prolong the lifespan of your items. Explore our range of high-quality ultrasonic cleaners and find the perfect model to suit your cleaning needs today!

FAQs About Ultrasonic Cleaners

Q: Can ultrasonic cleaners damage delicate items?

A: Ultrasonic cleaning is gentle and non-abrasive, making it safe for delicate items. However, it’s important to choose the right frequency, temperature and cleaning solution to avoid potential damage.

Q: How long does the ultrasonic cleaning process take?

A: The duration depends on the level of contamination and the items being cleaned. Most cleaning cycles range from 3 to 20 minutes.

Q: Do I need to use a specific cleaning solution?

A: Yes, using a suitable cleaning solution enhances the cleaning process. Water alone may not be sufficient to remove certain types of contaminants.

Q: Can I use an ultrasonic cleaner for multiple types of items?

A: Yes, ultrasonic cleaners are versatile and can be used for a variety of applications. However, it is important to clean the tank and change the solution when switching between different types of items to avoid cross-contamination.

Q: Are ultrasonic cleaners energy-efficient?

A: Ultrasonic cleaners are generally energy-efficient, especially when compared to manual cleaning methods. They require less water and often use less energy overall, making them an eco-friendly option.

This guide aims to help you better understand ultrasonic cleaners, their uses, and how to get the best results from them. For more information or to browse our products, visit our Pro Series ultrasonic cleaners