What makes a good ultrasonic cleaner?

These 7 factors will help you answer the questions “how do I choose an industrial ultrasonic cleaner and what is the right ultra sonic cleaner for your cleaning application”.

-

Ultrasonic cleaner frequency

What frequency is best for ultrasonic cleaning or as some refer to as ultrasound cleaning?

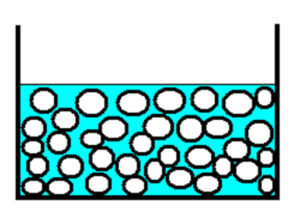

Ultrasonic cleaning is a process that uses an appropriate cleaning agent and ultrasound (usually from 20–400 kHz). The ultrasonic cleaning frequency must match the cleaning application. Different frequencies produce different results. The most common cleaning frequencies range from 25kHz to 80kHz. Lower frequencies such as 28 kHz produce fewer and larger bubbles that are aggressive for heavy duty industrial applications. 40-80 kHz and up produces very tiny bubbles packed tightly together which create a gentle scrubbing action for semi-conductors and high-end electronic components. 40kHz produces a large number of smaller bubbles that produce powerful cavitation. Omegasonics factory sets at 40 kHz which is the best frequency for industrial and commercial cleaning applications.

-

Ultrasonic generator power

How much power do you need for an ultrasonic cleaner?

The power of an ultrasonic cleaner is measured by watts per gallon. The correct wattage for our tank capacity is important (Watts/Gallon) for efficient ultrasonic cleaning. When cleaning with ultrasonics, always use a higher power level for heavy contamination. The ability to control power output is important because it allows you to tailor the output to cleaning needs. The ultrasonic generator is what produces the power which sends the signal to the ultrasonic transducer that produces ultrasonic cleaning waves in the tank.

-

Ultrasonic cleaning solution soaps, chemicals and detergents

How do you know what is the best ultrasonic cleaning solution for cleaning your item?

Ultrasonic cleaning detergents dissolve and dislodge surface residues. Not all cleaning solutions work effectively in ultrasonic equipment; some general-purpose cleaners break down at temperatures as low as 140F and cavitation action can cause some general chemicals to break down into their components. Omegasonics’ chemicals are formulated for specific cleaning applications and designed not to breakdown during cavitation. Different soaps work for different applications and materials. For example, alkaline chemicals remove dirt and smoke while acidic solutions remove corrosion and heat scale. If you are cleaning a delicate item then you will want to use a ultrasonic cleaning solution with a lower pH such as 10.0, if you are cleaning a general item such as glass or plastic then you will want to use a solution that has a pH around 11.3-11.8 and with metal items you will use a solution that has a pH at around 2.0 to remove rust. Can you use tap water in an ultrasonic cleaner? The answer is yes, but if you are cleaning any type of electronics in the ultrasonic cleaner than de-ionized water is recommended.

-

Ultrasonic cleaning temperature

What temperature do I use when cleaning my item in an ultra sonic cleaner?

Most ultrasonic cleaning is done at temperatures ranging from 100°F to 150°F. The correct temperature will expedite the cleaning process. Start with lower temperatures & work up to higher temperatures. All of our machines come with digital temperature controllers.

-

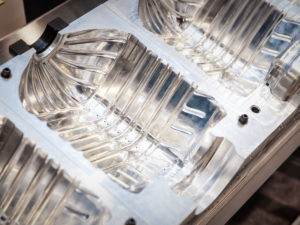

Ultrasonic tank part loads and tank sizes

What size ultrasonic cleaning tank do I need?

Part loads relates to the mass of the items being cleaned within the ultrasonic tank, increased part loads require more energy to process; small loads will clean faster than larger loads due to available energy for the load. If you overload your tank with parts, it will decrease the amount of cavitation that is hitting the surface of the parts being cleaned and will not only affect the cleaning process but will also affect the cleaning consistency. If you are cleaning a lot of parts at once then you will want a larger tank to accommodate your cleaning needs. Omegasonics also offers custom tanks.

-

Material makeup

What can ultrasonic cleaners clean?

You probably have heard of ultrasonic cleaners mostly for cleaning jewelry but did you know that you can clean any hard durable item in an ultrasonic tank? The number of items that can benefit from ultrasonic cleaning is vast. The reason? There are just two basic “eligibility requirements” before something can be cleaned in this manner.

The cavitation that powers ultrasonic cleaning and scrubs contaminants off parts will only occur in a liquid environment. Ergo, the item must be one that won’t be damaged by immersion. Some of the things on that list might surprise you. For instance, most of us would react with horror at the idea of combining electronics and water, but as long as proper drying techniques are used, an ultrasonic cleaner will not only clean electronic devices, but clean them more quickly and completely than any other method. The second requirement is that the part can be dried relatively easily. This eliminates items that are absorbent, but most others can simply be air dried with a blower.

For this reason, ultrasonic cleaning is used to remove unwanted materials from everything from jewelry to long rifles, from super-delicate lenses to massive engine parts, from surgical instruments to motherboards.

You may be wondering if ultrasonic waves will damage relatively brittle materials, such as glass or ceramics. Ultrasonic cleaning is perfectly safe for these materials.

What should you not put in an ultra sonic cleaner? Do not put anything textile such as clothing, shoes, rugs and stuffed animals. They absorb the ultrasonic cavitation.

-

Ultrasonic cleaning time

How long does an ultrasonic cleaner take to clean?

There are many factors that determine how long an item will have to remain in the ultrasonic tank for the cleaning process, including: “frequency, power, soap, temperature, load, and material”, also what type of dirt or oil is on the item. Cleaning normally lasts between three and six minutes, but can also exceed 20 minutes, depending on the object to be cleaned. All of our machines come with digital timers that allow you to be able to set your desired cleaning time.

What are the advantages of cleaning with ultrasonics and ultrasound cavitation?

- Efficient – Ultrasonic cleaning provides the ability to clean baskets of parts rather than individual items.

- Thorough – Ultrasound is the most thorough cleaning method known to science. Contents cleaned manually by hand will never be as clean as contents processed ultrasonically. Ultrasonic bubbles can reach areas impossible to access by brushes or sponges

- Gentle – The ability to control the cleaning variables allows the same equipment to clean everything from industrial parts to delicate crystal and China.

- Consistency – Cleaning with ultrasonics is always consistent.

For more information on choosing the best ultrasonic cleaner in 2021 watch our video below.